Bag Manufacturing Processing Services

We will address your packaging material manufacturing needs.

Such as:

Producing a bag from the original raw film plastic

Ready-made bag special processing

Undertake production of woven bags

Regarding requests and inquiries

For any inquiries related to our services, please contact us via our contact form and choose “About Services” as your subject.

Our sales representative will contact you within one business day.

We can also serve other processing not mentioned on this page.

Please do not hesitate to contact us.

Polybag manufacturing

Flat poly bag

Bottom sealed poly bag using tubular poly film.

Widely used in different applications for packing assorted goods.

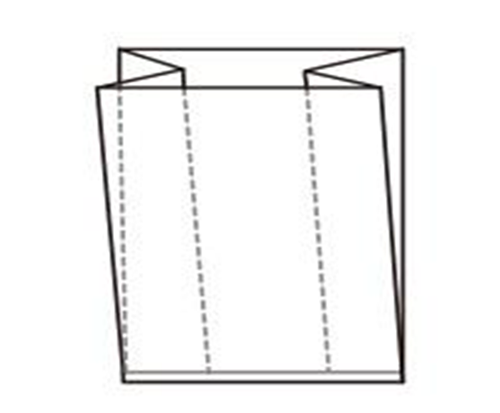

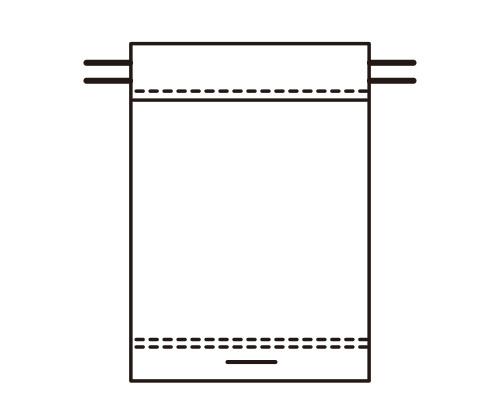

Gusset bag

Bottom sealed bag using gusset-shaped polyethylene film.

Suitable for packing box type objects and other bulky items.

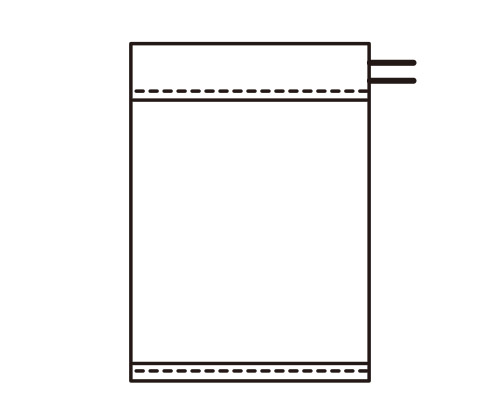

Partly sealed bag

A sealing process that produces partial sealing of the bag.

More efficient than just creating holes in the post process.

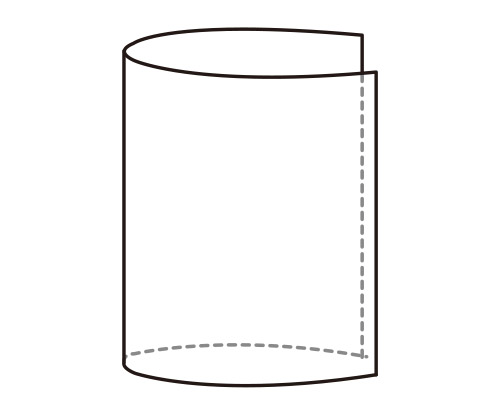

Tube cut

Cylindrical (tube) polyethylene film cut processing.

Often used for packing calendars and posters.

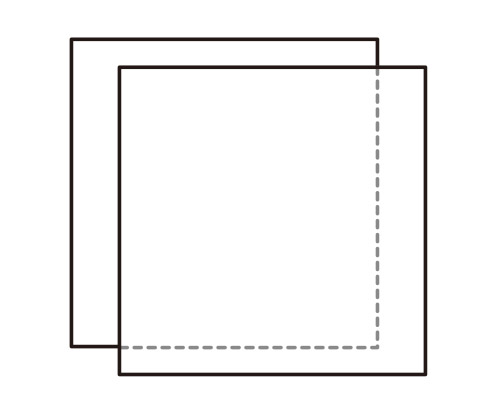

One side open cut

Slitting and cutting one side of cylindrical (tubular) polyethylene film.

Double sheet cut

Slitting and cutting of both sides of cylindrical (tubular) polyethylene film.

Woven bag manufacturing

Woven bag production

We provide special sewing process using woven polyethylene raw fabric in accordance with the customer’s specification. It can be attached with fasteners, velcro tapes or ropes.

Mostly used for storing chaff, rice husk, and waste materials.

Sandbag production

We manufacture sandbags using woven polyethylene raw fabric in accordance with the customer’s specification.

Commonly used for packing sands and gravels but also used for piling rocks and soils for soil erosion prevention. Good resistance against weight and more durable than woven bags.

Other manufacturing processes

Die Cutting

Punching process to remove an elliptical shape to create a handle for the bag.

Ideal bag for apparels and handout materials such as pamphlets.

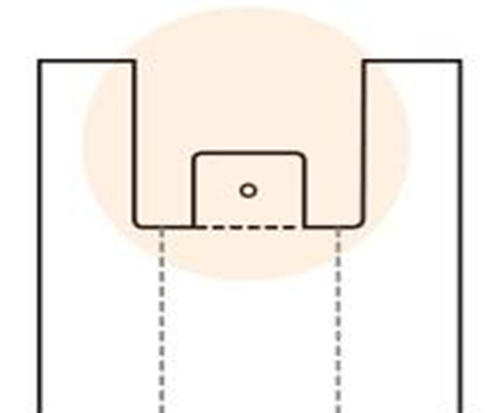

Corner cutting

Punching process to create a regular handle on a gusseted bag.

Used mainly as a shopping bags for supermarkets and convenience stores due to its convenience.

Air holes

Punching process to create air holes in a designated location of the bag.

Bag air vents commonly used for packing flowers and vegetables and air vents to prevent goods from bulging.

Semicircular perforation

A process of creating a semicircular perforation at the bottom of the bag.

With perforation, it is easy to tear particular portion of the bag to take out contents without using cutters or scissors.