Quality Management Production System

Plastic Bags

Production Preparation

Appearance and thickness inspection

Production Test

Dimension, tensile and appearance inspection

Mass Production

Dimension, tensile and appearance inspection after 100 sheets

After that, sampling inspection

Sandbags and Woven Bags

Production Preparation

Appearance and thickness inspection

Production Test

Dimension, tensile and appearance inspection

Mass Production

Quantity check, foreign substance check, and appearance check

Dimensional check

Ropes

Production Preparation

Raw material inspection

Production Test

Dimension, tensile and appearance inspection

Mass Production

Sampling inspection

Main Inspection Tools

In addition to the above inspection activities, we conduct various inspections conducted by third-party institutions (public and private inspection institutions) for all products requested by our customers.

For example,

- Qualitative analysis (lead, cadmium, bromine, chromium)

- Fluorescent X-ray analyzer (ink hazardous inspection)

- Jumbo sandbag durability test

- Analytical test (fabric hazardous inspection)

It is possible to conduct product inspection by any third party inspection institutions for any products requested by customers who need third-party quality certifications. Along with it, we established standardization of quality standards with domestic and overseas production bases by adding our own quality standards table based on Japanese Industrial Standards (JIS).

Hygiene Operating Procedures

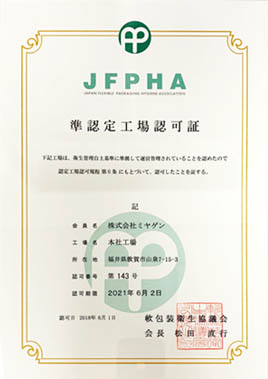

Approved as a semi-accredited factory by the Flexible Packaging Hygiene Association.

Japan Flexible Packaging Hygiene Association (JFPHA)

A semi-accredited factory

Grant Number : 143

Approval Date : June, 1st 2018.

Overseas Production Base Quality Control Management

Checking of standard specifications (product drawings, specification sheets, etc.) with the production on a daily basis.

Regular factory audit.

Implementation of pre-shipment inspection.

To aim for a zero customer claim.

Filing and regular reviews of all customer’s claim history and set standards to prevent the claim from recurring.

Centralized implementation and standardization of all quality control related documents and materials.